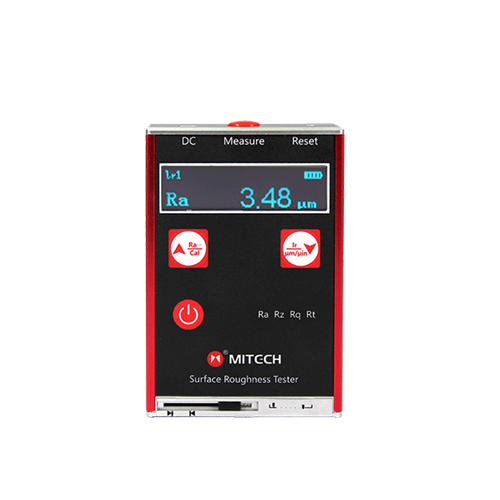

Pocket Surface Roughness Tester MR100

Add to Wishlist1 in stock

Contact for a quote.

Request for Quotationช่องทางการสั่งซื้ออื่น ๆ

ติดต่อทาง Line

@santatech

ติดต่อทาง Line

@santatech

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางโทรศัพท์

02-1013454

ติดต่อทางโทรศัพท์

02-1013454

Description

MITECH MR100 pocket surface roughness tester instrument, based on the principle of needle drawing method, with advanced sensor systems and DSP technology, it can detect the mental surface roughness accurately and sensitively. And it’s the latest product. High precision, easy to carry, stable and reliable, it is widely used in a variety of metal and non-metallic surface roughness detection. It’s a necessary products that improve production efficiency, reduce the cost of production.

![]() Function & application

Function & application

- a variety of machined parts of the roughness detection;

- all kinds of metal and non-metallic processing surface detection;

- detection, measurement, commodity inspection and other departments sampling;

- large parts and production lines roughness quality control links.

![]() Working Principle

Working Principle

Needle scanning method, start the instrument and do the measurement after placing the instrument on the surface of the work-piece. The inside precision driven component of instrument drive the probe slide straightly along the surface of the workpiece while the probe with its sharp stylus detecting the surface of the workpiece. At the same time the workpeice surface roughness will make the stylus displacement along vertically. This displacement makes the probe piezoelectric wafer deform and output electric signal. After amplified and level translated, this signal will go to the data acquisition system.DSP chip will conduct digital filtering and parameter calculation for the collected data. And the measurement results will be displayed on the OLED display screen.

![]() Working Conditions

Working Conditions

Working conditions

Temperature: 0 ~40 °C

Relative humidity: < 80%.

No vibration, no corrosive media around

Storage conditions

Temperature: -20 ~60 °C

Relative humidity: <90%.

Transport conditions

Circulation condition: Third level.

![]() Instrument Features

Instrument Features

- Measurement parameters: Ra, Rq, Rz, Rt.

- Using high-precision piezoelectric crystal transducer.

- Mechatronics design, smaller and lighter.

- 128×32 OLED dot matrix LCD displays clearly without backlight.

- Using DSP chip execute control and data processing.

- Built-in lithium polymer rechargeable battery and charging protection circuit.

- Mini-USB charging interface, available for phone charger.

- Widely used in a variety of metal and non-metallic surface roughness detection

- Set the sensor probe protection door, after the end of the measurement should be closed to protect the door to.effectively protect the sensor probe;

- Meet the relevant standards at home and abroad;

- Can manually select the sampling length.

| Net Weight | 200g |

| Dimensions: | 105 mm×70 mm×24 mm |

| Charger | DC 5V, 500mAh |

| Battery | 3.7V Lithium-polymer battery |

| Sensor head pressure | ≤0.5N |

| Measuring force and change rate | ≤0.016N, ≤800N/m |

| Probe tip’s arc radius and angle | 10.0±2.5 μm, 90° |

| Indication variation | <12% |

| Indication error | ±15% |

| Measurement range(μm) | Ra: 0.05 ~ 10.0, Rz: 0.1 ~ 50 |

| Access length(mm) | 1.25, 4.0, 5.0 |

| Lr(mm) | 0.25, 0.80, 2.5 |

| Stroke length(mm) | 6 |

| Measurement parameters(μm) | Ra, Rz, Rq, Rt. |

SANTA TECHNOLOGY CO.,LTD. (Head Office)

35/218 Moo. 2, Leabkhlongsam Rd., Khlongsam, Khlongluang, Pathumthani 12120

Call 02-101-3454 ,089-006-2766

Fax 02-101-3453

Mail. santatech@gmail.com

Line : @santatech

Web : https://santatechnology.com/