แหล่งจ่ายสำหรับเครื่องเชื่อมสปอต Amada miyachi standard mda-10000a polarity switchable mda-5000a

Add to Wishlist1 in stock

ติดต่อขอใบเสนอราคา

ขอใบเสนอราคาช่องทางการสั่งซื้ออื่น ๆ

ติดต่อทาง Line

@santatech

ติดต่อทาง Line

@santatech

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางโทรศัพท์

02-1013454

ติดต่อทางโทรศัพท์

02-1013454

รายละเอียด

แหล่งจ่ายสำหรับเครื่องเชื่อมสปอต Amada miyachi standard mda-10000a polarity switchable mda-5000a

Fine Spot Welding Power Supply.

Fine spot welding (resistance welding) is a joining method using heat generated from resistance caused by placing electrodes in contact with workpieces to apply force and let current flow into workpieces. It is an eco-friendly joining method without using solder and is employed in a variety of industrial fields.

Precision welding is the specialty of AMADA MIYACHI's fine spot welders. AMADA MIYACHI's technologies are especially used for welding of sensors, ECUs, bus bars, batteries, and motors in a variety of industries such as home appliance, automobile, mobile telephone, and medical equipment industries.

AMADA MIYACHI has a lot of knowledge and experience in fine spot welding techniques and dominate the market in areas requiring fusing, seam welding, projection welding and reflow welding.

AMADA MIYACHI's extensive lineups including welding power supplies, transformers, weld heads, and electrodes enable you to find the ideal system for your applications.

We also offer equipment for the quality control of fine spot welding, as well as pulse heat controllers, which make plastic welding possible, and our own unique pulse TIG welders (for arc welding).

Additionally, we have developed automated or semi-automated process machines that incorporate fine spot welders in order to respond to an increasingly diverse range of customer needs.

Standard: MDA-10000A.

Polarity switchable: MDB-5000A.

Short-time, large-current welding by multiple connection of power supplies.

Features.

Multiple connection of power supplies realizes high power welding at short time!

・MDA-10000A :Maximum twelve units connectable (One master and eleven slave units)

Design your own system to add power supplies as much as you need to obtain enough power.

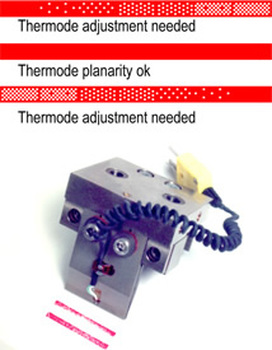

At left: Customised weld head (Maximum weld force: 20kN).

One master unit to control all connected units.

It does not necessary to set the weld schedule at each unit anymore. It needs to set only at a master unit which controls all slave units.

All units' current feedback.

The current feedback feature controls to stabilize current of all connected units collectively.

Three control types to choose from.

Plarity switchable type: MDB-5000A.

・MDB-5000A:Connection of a master and a slave unit.

Three control types; which are same as MDA-10000A, can be selected.

Peltier effect can be reduced and shape of nugget can be uniformed.

Specifications.