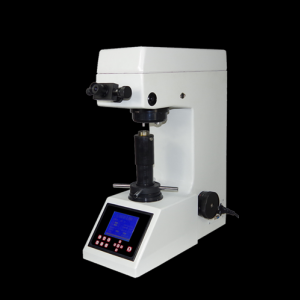

Digital Automatic Turret Vickers Hardness Tester MHVS-10Z

Add to Wishlist1 in stock

Contact for a quote.

Request for Quotationช่องทางการสั่งซื้ออื่น ๆ

ติดต่อทาง Line

@santatech

ติดต่อทาง Line

@santatech

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางโทรศัพท์

02-1013454

ติดต่อทางโทรศัพท์

02-1013454

Description

Mitech MHVS-Z Series Digital Automatic Turret Vickers Hardness Tester, based on the principle that positive quadrangular pyramid diamond indenter presses the surface of thesample to produce indentation.By measuring the diagonal length of the indentation to achieve the measurement of the hardness of the material can be for small specimens, thin specimens, surface coating, heat treatment of the workpiece surface Vickers hardness test. With stable performance, strong structure, high reliability, simple operation, digital display,adopt high magnification optical measurement system, adjust the cold light source, photoelectric sensing technology and computer-aided means it has a powerful function. It is widely used in the fields of metal processing, electronics industry, mold parts, watch manufacturing, engineering quality inspection and so on. It is an ideal hardness tester for material research and testing.

![]() Function & application

Function & application

- Small, thin specimen.

- Surface heat treatment workpieces.

- Surface coating

- Glass, ceramics, agate, artificial gemstones and other more brittle, hard non-metallic materials

![]() Working Principle

Working Principle

Micro-Vickers (or Knoop) hardness test principle is that put the provisions of the positive pyramid diamond indenter into the sample surface(with fixed experimental force) and maintain a certain length (holding), and then unloading. Finally, there is a positive quadrangular pyramid or kenup indentation with a square surface on the surface of the specimen. Then we can attain the area of indentation via measuring the length of the diagonal by a micrometer eyepiece. Then the corresponding Vickers (or Knoop) hardness values are obtained.

Usually Vickers hardness values can be converted according to the following formula

×test force / indentation surface area≈0.1891 F/d2

Note:

HV, Vickers hardness symbols

F, test force

d, the arithmetic mean of of the two diagonal d1, d2

![]() Working Conditions

Working Conditions

- Operation Temperature:18~28℃

- Relative Humidity:≤65%

- In an environment free from vibration,no corrosive medium.

- Installed on a flat basis.

![]() Instrument Features

Instrument Features

Widely used in micro-specimen, thin specimen, surface coating, heat treatment of workpiece surface samples and etc.Vickers hardness test to meet different demands of scientific research institutions, precision machining and quality inspection departments and other materials research

Adopt automatic turret device, can be self-conversion indenter and microscopic eyepiece, high efficiency

ESupport Brinell, Vickers and other hardness units convert.

Equipped with a variety of small load Vickers hardness scale spare

Equipped with high-speed thermal printer, real-time print test results

Modeling novel, strong structure, the use of diamond indenter, strong wear resistance, high reliability, intuitive readings, accurate measurement

Host stability is good, the workpiece surface quality and man-made factors on the hardness of the test results less impact

The use of electronic automatic loading system to control the main test force, eliminating the need to load the weight, the operation more convenient

Using large-screen LCD liquid crystal display, easy to operate, can visually display the test results

Using high magnification optical sensor system and high precision photoelectric sensing technology, test point positioning accuracy, test results more accurate

Adjustable cold light source measurement system, through the software to control the light source strength

Optional photographic device, can be achieved on the measured indentation and material microstructure to shoot for future analysis

Meet ISO 6507, ASTM E92, JIS Z2244, GB / T4340.2 and other relevant domestic and foreign standards.

| Test force | 2.94N、4.9N、9.8N、29.4N、49N、98N |

| Measurement range | 8HV0.3~2500HV10 |

| Hardness symbol | HV0.3、HV0.5、HV1、HV3、HV5、HV10 |

| The conversion mode of the head and the objective lens | Automatic operation |

| Loading and unloading mode | Automatic operation |

| Magnification of measuring microscope | 200x(testing) 100x(observing) |

| Minimum detection unit | 0.0625μm |

| Maximum height of applicable materials | 160mm |

| Test to secure the load time | 0~60s |

| Maximum distance from the center of the head to the machine wall | 135mm |

| Display attributes | Large screen LCD digital |

| Power supply | AC220V/50Hz |

| Dimension of Exterior | 540*220*650mm |

| Machine weight | 40kg |

SANTA TECHNOLOGY CO.,LTD. (Head Office)

35/218 Moo. 2, Leabkhlongsam Rd., Khlongsam, Khlongluang, Pathumthani 12120

Call 02-101-3454 ,089-006-2766

Fax 02-101-3453

Mail. santatech@gmail.com

Line : @santatech

Web : https://santatechnology.com/