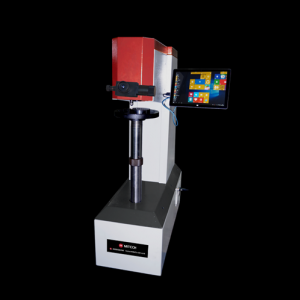

Automatic Brinell Hardness Tester MHBS-3000-XYZ

Add to Wishlist1 in stock

Contact for a quote.

Request for Quotationช่องทางการสั่งซื้ออื่น ๆ

ติดต่อทาง Line

@santatech

ติดต่อทาง Line

@santatech

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางอีเมล์

santatech@gmail.com

ติดต่อทางโทรศัพท์

02-1013454

ติดต่อทางโทรศัพท์

02-1013454

Description

Mitech MHBS-3000-XYZ Automatic Brinell Hardness Tester, based on the mechanical principle of hard alloy indenter pressing into the sample surface to produce indentation, realizing the material hardness measurement by measuring the diameter of the indentation,The use of photoelectric sensor system to high magnification optical measurement, equipped with automatic turret device, high sensitivity touch screen operation interface, can achieve automatic loading and unloading of electronic, automatic indentation marks, microscopic auto focus measurement indentation diameter, GB / ASTM hardness automatic conversion, automatic test report and other functions, easy to operate, high detection efficiency. It can meet the hardness testing requirement for the quality control and qualified assessment of the workpiece sample. It is widely used in metal processing and manufacturing, various metal material’s failure analysis and other fields like colleges and research institutions. It’s to improve the work efficiency, product qualification rate, saving production costs necessary professional precision testing equipment.

![]() Function & application

Function & application

Metal processing industry quality control links

Universities teaching and demonstration test

The failure test of metal material

The material hardness test of scientific research institutions

![]() Working Principle

Working Principle

Hardness is not a simple physical quantity, but a reflection of the material elasticity, plasticity, strength and toughness .and hardness test is the most simple mechanical testing method to determine the metal material performance. Also one of the important means to judge the products quality.

Brinell hardness test: Test force(F) is on the steel ball with certain diameter(D) , pressed on sample surface. After a period of time, cancel the force. The indentation diameter is get by measuring with micrometer ocular,thus to calculate the average pressure(N/mm²).

![]() Working Conditions

Working Conditions

Working Temperature:18℃~28℃;

Relative Humidity:≤65%;

Clean environment, no vibration;

No corrosive media around.

![]() Instrument Features

Instrument Features

Widely used in metal processing and manufacturing, various metal material’s failure analysis and other fields like colleges and research institutionsand other fields;

High degree of automation, accurate measurement, suitable for large demand or high precision measurement of high-end users.

Equipped with portable high-definition USB camera, ergonomic design, feel comfortable, delicate and durable.

Easy to operate, can automatically identify the edge of indentation, automatic removal of burrs to achieve accurateindentation measurement, synchronous display.

With threshold overrun automatic alarm function, apply to the bulk of finished products or semi-finished pieces of paper-by-piece detection.

Image and the corresponding measurement data files can be set to automatically store, open, store, print, modify, call and other operations, generate measurement reports;

Real-time statistical measurement data, display the maximum, minimum, average, deviation, CP, CPK and so on.

The automatic turret mechanism can realize the automatic switching function between the objective lens and the indenterand improve the detection efficiency.

Using touch screen display interface, display operation integration, simple and intuitive, the technical requirements of the operator is not high;

Equipped with excellent performance of the carbide indenter, high hardness, wear resistance, good toughness, while high

temperature, corrosion resistance, to ensure that the instrument measured standard, stable and reliable;

Equipped with high-speed thermal printer, you can quickly print out the test data;

According to ASTM_E140, DIN 50150, GBT_1172 and other different standards for hardness conversion;

Diameter measurement accuracy of up to 0.001mm, meet ASTM E 10, GBT 231, ISO-6506 and other standards;

-

The power series 612.5N(62.5kgf)、980N(100kgf)、1225N(125kgf)、1837.5N(187.5kgf)、 2450N(250kgf)、4900N(500kgf)、7350N(750k Test force accuracy 0.1% higher than the average Brinell hardness of 1% (1000Kgf above) Measuring range 8 – 650 HBW Conversion scale GB / automatic Brinell scale HBW2.5/62.5、HBW2.5/187.5、HBW5/125、HBW5/250、 HBW5/750、HBW10/100、HBW10/1500、HBW10/3000、 HBW10/250、HBW1 Testing Force Application Mode Automatic (loading, holding, unloading) Indenter objective lens conversion mode Automatic Indentation measurement Automatic Image focus Automatic or manual Turret Automatic or manual Camera (pixel) 1.3 million / 3 million Indentation measurement Automatic or manual Hardness value display Automatic display usage LCD touch screen Test force holding time 5~60s Minimum division 0.001 mm Applicable material maximum height 400mm Max distance from head to body 250mm Test report Automatic Voltage AC 220V/50Hz Size 760*320*1050mm Total Weight 200kg

35/218 Moo. 2, Leabkhlongsam Rd., Khlongsam, Khlongluang, Pathumthani 12120

Call 02-101-3454 ,089-006-2766

Fax 02-101-3453

Mail. santatech@gmail.com

Line : @santatech

Web : https://santatechnology.com/